clive f

Busy user

my `98 Vette had a duff steering wheel position sensor, new ones not available for this year, bought a very expensive second hand replacement from a US breakers, which I believe is working, , its now fitted onto the car, I had to remove the steering rack to fit a new harmonic balancer so this seemed like the ideal time to replace the sensor as well, the sensor centering pin wasn`t removed until the new sensor was located into the green housing on the column, and the wheel not turned after this, so all put back together fine.

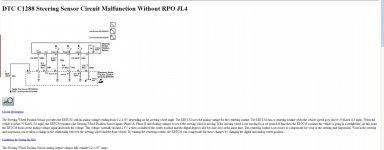

driving the car after the first couple of miles the usual TCS light pops up, and error code TCS1288, SWPS returns, I`ve also had a service message to center steering, and from what I`ve been reading on the usa forums its possible to center the sensor once its been replaced.

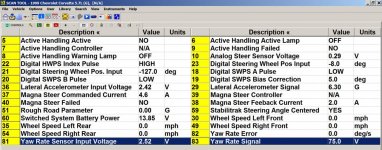

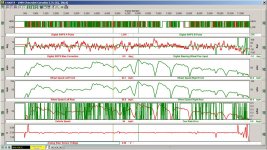

I`m fine mechanically but electrics are the work of the devil! plugging in the tech 2 Ive run a steering test, see photo, should analoge and digital both read zero at the same time?have also taken a screen shot of the data on the magnasteer, with the data there, which wasn`t evident on my old sensor, I assume that the replacement sensor is working, but, somehow it needs centering.

so the sensor itself cannot be moved as its fixed into the green housing on the steering column, that leaves the option to either change the tracking to line up with the voltages on the meter, or, somehow change the voltages in the sensor reading?

I`m now at a loss, there are countless threads on various forums talking about replacing the sensor, but nothing I can find detailing how you can actually centre it, I have the 4 big reg GM service manuals and there is no mention of this centering in any of them, so perhaps someone on here in the UK might have some knowledge?

I could take it to Ian Goss, or Top Cats, but I`m on the Isle of Wight so I`d like to be able to crack it myself before I have to spend £100 plus just to get on the car ferry.

driving the car after the first couple of miles the usual TCS light pops up, and error code TCS1288, SWPS returns, I`ve also had a service message to center steering, and from what I`ve been reading on the usa forums its possible to center the sensor once its been replaced.

I`m fine mechanically but electrics are the work of the devil! plugging in the tech 2 Ive run a steering test, see photo, should analoge and digital both read zero at the same time?have also taken a screen shot of the data on the magnasteer, with the data there, which wasn`t evident on my old sensor, I assume that the replacement sensor is working, but, somehow it needs centering.

so the sensor itself cannot be moved as its fixed into the green housing on the steering column, that leaves the option to either change the tracking to line up with the voltages on the meter, or, somehow change the voltages in the sensor reading?

I`m now at a loss, there are countless threads on various forums talking about replacing the sensor, but nothing I can find detailing how you can actually centre it, I have the 4 big reg GM service manuals and there is no mention of this centering in any of them, so perhaps someone on here in the UK might have some knowledge?

I could take it to Ian Goss, or Top Cats, but I`m on the Isle of Wight so I`d like to be able to crack it myself before I have to spend £100 plus just to get on the car ferry.