teamzr1

Supporting vendor

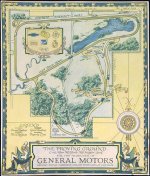

GM owns one of the largest test tracks in the world for 100 years now which is the Milford Proving grounds in Mi

Interesting facts about GM’s top secret development site:

Interesting facts about GM’s top secret development site:

- What it cost: GM paid about $100,000 for the property in 1923. It has grown to occupy about 4,000 acres of land and has lakes, where employees can fish. It's teaming with wildlife and contains the highest point in Oakland County.

- No "S" on the end: The full name of the site is the General Motors Milford Proving Ground. But like Meijer, Kroger or Ford Motor Co., Milford Proving Ground also falls victim to many Michiganders putting an “S” on the end of it that does not belong there, calling it the “proving grounds.” It is not plural.

- Top secrets: There are secret labs with state-of-the-art virtual technology where engineers can drive on the moon and do the GMC Hummer EV's famous Crab Walk long before the vehicle ever did it on the road.

- Like a city with services: The site, which operates 24/7 365 days a year, is self-contained, using its own wells for water; it has a wastewater treatment facility, and it employs certified firefighters, licensed EMTs, hazardous material's response, confined space rescue team and road patrol officers. It has a fully staffed medical department.

- Why you won't get in: The site is heavily guarded because all of GM's prototypes of future cars are there, hidden from spy photographers either behind closed doors, under camouflage tape or for super top-secret projects tested only in the dark of night to shield it from drone photos.

- Special driver licenses needed: The engineers who work at the grounds are trained to drive like professional race car drivers so that they can test vehicles to the limits. The level of license is based on the speed a driver is allowed to go. GM has about 81,000 salaried employees globally, but fewer than 100 have passed the driving tests to do the top-speed test-driving at the proving ground.

- How many miles of tracks: There are 147 miles of test courses, including the Milford Road Course,

- a racetrack that mimics parts of the famous Nurburgring in Germany.

- Every kind of roadway: The road surfaces of GM's tracks vary from dirt roads, to hills, to bumpy concrete with purpose-made potholes, to six lanes of banked concrete on a 5-mile Circle Track, to a straightaway with no speed limit, to the speedway-ready 3-mile Milford Road Course.

- What that asphalt is: The ground's "Black Lake" is a slab of black asphalt that in the sunlight gives the illusion that it is water. It is the size of 59 football fields and is one of the largest vehicle dynamics pads in the world, used for a variety of tests on various aspects of cars, such as vehicle handling.

- Replica of Belgian road: One of the smaller test tracks that is no less intriguing is GM's Belgian Block. It is a 2-mile-long replica of the real brick road that ran from Antwerp to Brussels, which was discovered during World War I by U.S. soldiers.

- Hollywood knows about it: Portions of the "Transformers 4" movie were filmed at the proving ground. The filming locations included the Oval Track and the North/South Straightaway course. The Oval Track was painted with road markings to transport it fictionally to Asia.

- Where guardrails were born: The 130 miles of guardrails that line nearly every road on the proving ground reflect what you see along any major interstate. The rails were first developed at Milford Proving Ground, designed to absorb an impact and pull a car along the rail.

- Developing virtual technology: GM is investing millions in virtual technology to test the entire car's performance virtually before ever making a physical prototype and putting it on the road. Virtual technology can get new vehicles to market faster, saving millions of dollars in costs to build physical prototypes. One prototype of a car can cost $100,000.

- The VDTA ("Vehicle Dynamics Test Area"), also known as "Black Lake", is a 67-acre (270,000 m2) pad of blacktop for vehicle dynamics testing. Waterfowl have been known to try to land on this "lake" of asphalt. At the ends of the VDTA are two semicircle tracks used for accelerating vehicles up to high speed before entering the pad. A controlled low-friction area made of ceramic tiles is on one side of the pad. Another area is coated with the asphalt sealant and can be watered down to produce a low friction surface.

- The Oval Track is a 3.8 miles (6.1 km) circuit

- The Circle Track encloses the VDTA and is a 4.5 miles (7.2 km) banked circle. It has five lanes posted with speed limits increasing towards the outermost lane. The speed limit for the outermost lane is 100+ MPH (160+ km/h). Due to the banking, each lane can be driven at its posted speed all the way around the circle without needing to touch the steering wheel, given proper wheel alignment and tire pressures. The track surface is extremely hard "dolomite" concrete for wear resistance.

- The North/South Straightaway is 6.225 miles (10.018 km) in total length and includes two 2.5 miles (4.0 km) straightaways

- The East/West Straightaway is 3.1 miles (5.0 km) around and includes two 1.2 mi (1.9 km)straightaways

- "Seven Sisters" is a short course featuring seven tight curves, some level, some banked. It is one lane that can be driven in both directions, so only one car is allowed on the course at a time. This is used for testing vehicles under transient lateral acceleration loads.

- 12 Mile Road is a straight section of pavement which duplicates the historical surface texture of a section of 12 Mile Road near Detroit.

- The Ride and Handling loop is enclosed by the Circle Track and has varied surfaces and turns.

- The Vehicle Safety & Crashworthiness Lab includes a recently added rollover test facility.

- .