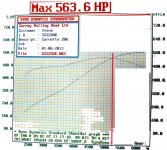

GM stopped the BS dyno results by starting with the C6s uses the SAE standards which is a engine dyno and not the crap non load bearing chassis dyno. Since then the numbers GM gives for flywheel HP and Torque is very close to realworld

But the fact is so called performance shops and vendors of performance parts use bogus chassis dyno results for marketing

Owners qho are dyno queens love non bearing types, hate load bearing as with those using braking or making equal loads give a far closer

truer results

I have caught chassis dyno shops lying results such as

1. Stick the weather station on top of the engine, that causing then a phony heat weather factor which then adds a bogus D/A factor

2. If you want poor results, do not properly strap down ass end, causing tire spin/slip

3. Then the after results is proper strapdown, thus higher result numbers.

4. Lying about the elevation in the calibration of the chassis dyno, add couple of thousand feet and then numbers will be factored in much higher then engine vehicles ability

DYNO CORRECTION STANDARDS

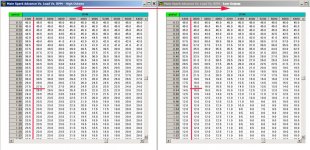

The most common are the SAE standards. The older J607 standard considers that the engine was run on a 60°F day with 0% humidity and a barometric pressure of 29.92 in-Hg or the newer SAE J1349 standard of 77°F (25°C) day with 0% humidity and a barometric pressure of 29.234 in-Hg (99 KPa).

Also the ECE standard is the same as the SAE J1349, but does not use mechanical efficiency in the calculations. The DIN standard which corrects to 68°F (20° C) day with 0% humidity and a barometric pressure of 29.92 in-Hg (101.3 KPa) and the JIS standard corrects 77°F (25° C) day with 0% humidity and a barometric pressure of 29.234 in-Hg (99 KPa), but uses different correction curves than the others (as a substitution for using mechanical efficiency factors).

Further, we have the J1995 corrects 77°F (25° C) day with 0% humidity and a barometric pressure of 29.53 in-Hg (100 KPa).

Since very few engines are actually run in these conditions we apply these correction factors so that it is possible to compare the results taken on different days. First lets just look at the weather correction, we will see the second section dealing with mechanical efficiency later.

Consider if you take a baseline run of a normally aspirated four stroke V-8 engine on a sultry day in late August, say 85°F and 85% humidity and 28.85 in-Hg and the engine produced 400 Hp. Then after you finished making all your modifications you retest the engine in late September when it is 55°F and 35% humidity and 30.10 in-Hg, the engine now makes 442 Hp.

That’s almost an 11 percent increase in Hp, however the engine is actually producing the exact same amount of horsepower according to the J607 correction values of 400 Hp * 1.1005 ≈ 440 Hp and 442 * 0.994 ≈ 440 Hp. If you had retested the engine in the same weather conditions it would have made 400 Hp again.

One more source of confusion about the SAE J1349 is all the different values quoted for the Barometric Pressure in inches of Mercury. If you search around you will find the base values are different. Some will quote 29.234 in-Hg and others 29.318 and others 29.380. How can they all be correct?

Well the calculations are done in KPa or millibars. These units are all true pressures, however inches of mercury, although considered a pressure unit, changes with temperature. This is because mercury expands as it gets warmer. Therefore 99 KPa at 32°F is 29.234 in-Hg and 99 KPa at 60°F is 29.318 in-Hg.

Now this may sound confusing, but these formulas were developed to attempt to allow standardize advertised hp ratings and comparisons.

The formulas are based on the amount of oxygen that is found in the air that the engine is breathing. The greater oxygen the more fuel can be burned and thus more horsepower. However, these formulas are not perfect.

They were developed empirically and are a good approximation for the variables of humidity, temperature, and absolute pressure. However, internal combustion engines develop power on many other variables and although it is possible to have the same correction factor at high temperature and pressure as low temperature and pressure, the engine will make different power.

The wetting effect and temperature differences are not perfectly compensated for. This gives rise to the “purist” touting that all engines must be tested at the same atmospheric conditions or else the results are useless.

In a prefect world this would be true, but this would be ludicrous. The cost of building an environmentally standardized test cell is well beyond the capabilities and cost of even large OEM companies and would give rise to even more deception in horsepower advertising.

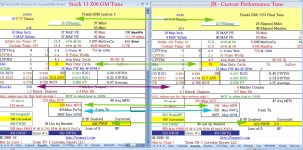

Now lets consider the next effect on the SAE standard that some other industrial standards do not include, the “Mechanical Efficiency” of the engine.

Which is basically the amount of energy the engine got from the fuel versus how much energy actually was produced at the flywheel. This is a measure that includes the frictional torque, viscous effect, etc. required to rotate the engine.

If we take the SAE standard that a four stroke normally aspirated engine consumes 15% of its’ developed horsepower to rotate the engine. This is another huge point of debate, but it does make sense.

If we want to correct the observed horsepower to a standard condition, it make sense that the friction required to rotate the engine does not change with added oxygen in the air. So in the last example the engine produce 400 Hp on that hot August day.

This time consider the SAE J1349 correction standard which has a correction factor of 1.0634. According to the SAE 15% standard it took 70.58 Hp (400 / 0.85 – 400 = 70.58) to overcome the friction from ring drag, bearings, valve train, etc.

Since this is a constant value no matter where the dyno test was taken, we know that the energy produced by the engine was actually 400 + 70.58 = 470.58 Hp. Now if we want to compensate for the atmospheric condition then we should use the amount of energy that the engine got from the fuel supply. So we take the 470.58 Hp * 1.0634 = 500.42 and then subtract out the constant Hp reading of 70.58. 500.42 – 70.58 ≈ 430 Hp.

Now it does make sense that the frictional torque is almost constant no matter how much oxygen was in the air, but the SAE flat rate 15% does not accurately cover all internal combustion engines.

It is a compromise. In the example above we used a normally aspirated 4 stroke V-8 engine, but what if it were a two stroke V-8 outboard engine.

It is quite obvious that the two stroke has much less frictional drag. It has no camshaft, timing chain, valves and springs, oil in the crankcase, etc.

Comparing these two engines with the same 15% friction losses does not work. That is why some higher end dynoing software calculate the friction losses on many different variables, like the displacement, stroke for piston speed, type of aspiration, number of strokes, type of fuel, and RPM.

Using this information will yield much greater accuracy in calculating a mechanical efficiency and therefore a much greater accuracy for in house comparisons between pulls. However, in order to advertise the value as SAE J1349 compliant you must usually use the SAE mechanical efficiency number.

Another way to get accurate mechanical efficiency is to use a dyno that can “motor” the engine, like an AC dyno.

Just measure the amount of power it takes to drive the engine and then use those values for your own custom mechanical efficiency. Once again though, you will need a high-end software package that will easily allow you to use the new efficiency or else you will be doing a lot of tedious and time-consuming hand calculations.

But once again, this solution is not perfect either. Many will argue correctly that motoring the engine is not the same because there was no heat, bearing loads, metal deformation, etc.

Some companies who are working on a particular engine family will actually test the same engine under many different conditions and develop their own correction table.

To these companies it is vital to know how their engines will perform under specific varying conditions. Consider snowmobiles that will operate at many different altitudes and temperatures, but they can pretty much discount the effects of humidity because the engine will almost always operate at temperatures below freezing.

However, it is critical that their engines perform well at extremely different barometric pressures. An exhaust designed to run at sea level will not perform well at all in the mountains. Further, the opposite is true for marine engines.

These engines are run most often at sea level, warm temperatures, and high humidity. Or a waste gated turbo engine that is pretty much impervious to even large barometric pressure changes. Thus the one size fits all SAE approach does not work well.

The debate over the validity of correction factors still lingers on, but they are the only way to make realistic comparison of your engines on different days.

There are, and always will be, unscrupulous competitors who advertise inflated horsepower gains by manipulating the correction factors, however they are eventually exposed at the races where it counts to the customer.

In order to perform accurate and credible results you must use some factors and try to conduct your tests under “similar” test conditions.

In fact, SAE requires that the corrections be less than ± 7%. So in the example above we would not be allowed to use the STD or standard J607 SAE factor of 1.1005 because it is correcting by more than 10%, however the SAE J1349 factor of 1.0634 could just barely be used.

www.autotrader.co.uk

www.autotrader.co.uk