Chuffer

CCCUK Member

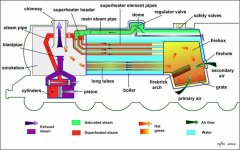

As many of you will know , I am a bit of steam locomotive enthusiast with a long history of firing , driving and restoring / repairing them .Some members that have a passing interest or just curious about the mechanical ins and outs of different types of engineering have suggested I start a thread on the locomotive overhauls I am involved with . So to that end , here we go ! The main object of our teams attentions at present is the heavy general overhaul of `King Arthur ` Class locomotive number 30777 ` Sir Lamiel` which is the only surviving example of its class as all the others were cut up for scrap many years ago . They were all named after characters from Arthurian legend and were designed for hauling express passenger trains on the then London & South Western Railway ( LSWR) . The first 10 members of the class were introduced to a design by R.W. Urie who was Chief Mechanical Engineer ( CME) of the LSWR in 1918 . A further 24 , `Sir Lamiel` included were built to a modified design in 1925 by the then CME of the LSWR , R.E.L. Maunsell . They had 3 pairs of 6ft 7 ins diameter driving wheels , a total weight of 138 tons 3 hundredweight and a Tractive Effort of 25,320 lbs / feet and a working boiler pressure of 200psi and powered by 2 outside mounted cylinders of 28 inch stroke x 20.5 inch bore with long travel piston valves . The large 8 wheeled tender carried 5000 gallons of water and 5 tons of coal .

Fortunately when 304777 was withdrawn from service by British Railways in October 1961 it was saved from he cutters torch and earmarked for preservation for the national collection and now belongs to the National Railway Museum (NRM) based in the UK York . The gallent knight has seen much use in the intervening years both on various Heritage Steam Railways and hauling charter trains on the national rail system all over the UK but has now been out of action for 2 years since it`s 10 year boiler insurance certificate expired . As a member of the 5305 Locomotive Association , the group has negotiated a custodianship agreement with the NRM to carry out the major overhaul and return the locomotive to active service on the Great Central heritage railway in Leicestershire and be certified for use once more on the national rail system in time to celebrate its 100th birthday in 2025 . A big ask but attainable provided we have no more Covid lockdowns and no really expensive nasties are found when the boiler goes of for a rebuild .

Here he is in all his glory when last in service . The nitty gritty technical stuff will follow in my next post .

Fortunately when 304777 was withdrawn from service by British Railways in October 1961 it was saved from he cutters torch and earmarked for preservation for the national collection and now belongs to the National Railway Museum (NRM) based in the UK York . The gallent knight has seen much use in the intervening years both on various Heritage Steam Railways and hauling charter trains on the national rail system all over the UK but has now been out of action for 2 years since it`s 10 year boiler insurance certificate expired . As a member of the 5305 Locomotive Association , the group has negotiated a custodianship agreement with the NRM to carry out the major overhaul and return the locomotive to active service on the Great Central heritage railway in Leicestershire and be certified for use once more on the national rail system in time to celebrate its 100th birthday in 2025 . A big ask but attainable provided we have no more Covid lockdowns and no really expensive nasties are found when the boiler goes of for a rebuild .

Here he is in all his glory when last in service . The nitty gritty technical stuff will follow in my next post .