Last triumph

Well-known user

Full disclosure, I'm not great with electronics so need real Jack and Jill descriptions.

I have a multi-meter and can use the basic functions.

Symptoms - temp gauge reads hard right, off the scale at all times - see pic....

This is irrespective of whether the ignition is on, off or whether the battery is disconnected or not.

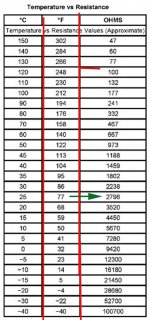

I'm told by a friend who quickly put a multi-meter across the sender and ground with the dark green wire removed that the sender looks okay, measuring 3.1k ohms at room temp.

With the dark green wire removed from the sender, I can measure 11.94V between the end of the green wire and ground only with the ignition on. From the same wire end to ground I measure 51 ohms resistance at all times, irrespective of whether the ignition is on or off or whether the battery is disconnected.

No condition or change in condition changes the position of the gauge needle from far right at all times - hot cold, running, off, nothing. Always hard right as pictured above.

I'm struggling to work out what to do next - some advise DO NOT disturb the bulkhead loom connector at the firewall, some say digging behind the gauge cluster is the last thing I want to do.....

Given the above, what steps do I take next to identify what/where the issue is and can anything be determined from the status and voltage/resistance readings so far from the various conditions I have posted?

Thanks in advance.

I have a multi-meter and can use the basic functions.

Symptoms - temp gauge reads hard right, off the scale at all times - see pic....

This is irrespective of whether the ignition is on, off or whether the battery is disconnected or not.

I'm told by a friend who quickly put a multi-meter across the sender and ground with the dark green wire removed that the sender looks okay, measuring 3.1k ohms at room temp.

With the dark green wire removed from the sender, I can measure 11.94V between the end of the green wire and ground only with the ignition on. From the same wire end to ground I measure 51 ohms resistance at all times, irrespective of whether the ignition is on or off or whether the battery is disconnected.

No condition or change in condition changes the position of the gauge needle from far right at all times - hot cold, running, off, nothing. Always hard right as pictured above.

I'm struggling to work out what to do next - some advise DO NOT disturb the bulkhead loom connector at the firewall, some say digging behind the gauge cluster is the last thing I want to do.....

Given the above, what steps do I take next to identify what/where the issue is and can anything be determined from the status and voltage/resistance readings so far from the various conditions I have posted?

Thanks in advance.

Last edited: