Fatbloke-Dim

Busy user

Hopefully, I've not overlooked anything for next weeks job. However, given my track record. I thought I ought to ask......what parts , apart from consumables such as oil, coolant , filter , are needed for lifting and replacing the heads on an LS 2? I'm putting lifters in ,so have the following to hand;

1. Lifters . Summit LS 7 's with their lifter trays.

2. head gasket/top end set. Felpro LS set.

3. Pushrods. Just in case, but can't hurt to swop 'em out whilst diving in there. Brian Tooley racing , stock length.

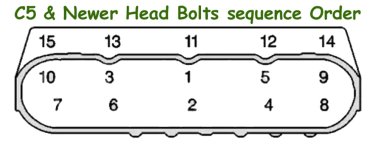

4. Head bolt set . Summit O.E.M. spec set.

What have I missed? Surprise me and tell me I have it all !!

1. Lifters . Summit LS 7 's with their lifter trays.

2. head gasket/top end set. Felpro LS set.

3. Pushrods. Just in case, but can't hurt to swop 'em out whilst diving in there. Brian Tooley racing , stock length.

4. Head bolt set . Summit O.E.M. spec set.

What have I missed? Surprise me and tell me I have it all !!