teamzr1

Supporting vendor

So you know that 2.73 rearend gear is not going to be ramping up RPM and MPHs as other sports cars

Second is the A4 is set up to drive like a Caddy since mostly waxers ( and women drive them

drive them

GM sets up the way the A4 reacts and shifts to be smooth and the suspension to be softer

Attached below is a file you can download

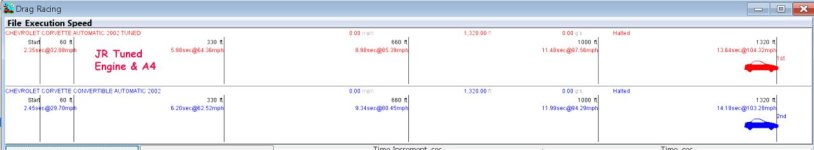

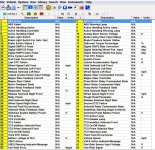

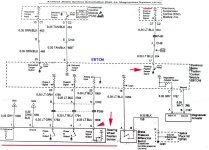

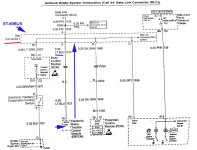

What I did is take a C5 with A4 and what you see is all the GM settings on how it commands the auto shifting

It is set up to slower shift times, reacts slower and is frankly calibrated for the waxers, so it drives nice

but has no balls when you get on it

Those with A4s and want to do some grassroots racing like an autocross will swap out that 2.73 gear to the MN6 rear gear of 3.42

Further, wanting more come to me and I redo all those setting I show you in the PCM so that it shifts quickly less latency

allows more torque, carries each gear to higher RPMs and MPH and downshifts much quicker

Take some time and look at the stock A4 setting in the text file attached

Second is the A4 is set up to drive like a Caddy since mostly waxers ( and women

GM sets up the way the A4 reacts and shifts to be smooth and the suspension to be softer

Attached below is a file you can download

What I did is take a C5 with A4 and what you see is all the GM settings on how it commands the auto shifting

It is set up to slower shift times, reacts slower and is frankly calibrated for the waxers, so it drives nice

but has no balls when you get on it

Those with A4s and want to do some grassroots racing like an autocross will swap out that 2.73 gear to the MN6 rear gear of 3.42

Further, wanting more come to me and I redo all those setting I show you in the PCM so that it shifts quickly less latency

allows more torque, carries each gear to higher RPMs and MPH and downshifts much quicker

Take some time and look at the stock A4 setting in the text file attached