Mad4slalom

Well-known user

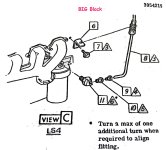

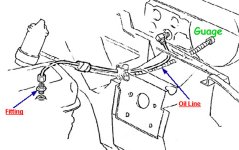

Hi again, well the oil leak that I was thinking was possibly s rear main seal showed itself today . It is the oil pressure gauge line where the thin copper pipe enters the gland nut on the block, it is pushing out there and running down the back of the block and over the outside of the bellhousing. I have not yet tried to see if the nut will tighten up a bit. Any ideas how to reach this? I was wondering if a crows foot wrench might get in there. The kits are now supplied with a plastic line I think, anyone tackled this job ? Looks a bit of a pain, is it hard to get the oil pressure gauge out and re fitted. Any tips or suggestions welcome, TiA