Oneball

CCCUK Member

Hi Oneball

Just a techie question as to the front spoiler used for cooling,

Will it sit lower to prevent air getting under the car and generating lift ?

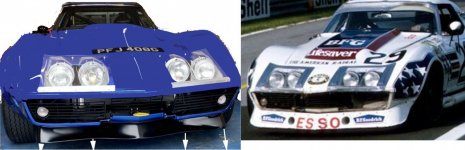

View attachment 13703

Yes, I reckon it’s about 2-3 inches deeper than standard. It’s the sort Greenwood used in 1972 but for Le Mans in 73 they went to a deeper one.