Also

Street cars need fan shrouds to allow the fan to provide airflow over the entire radiator and A/C condenser core areas when the vehicle is at little to no speed.

Those thicknesses result in a restrictive airflow, add crap building up them, then even more restrictive flow

Street use really needs a full shroud to overcome that

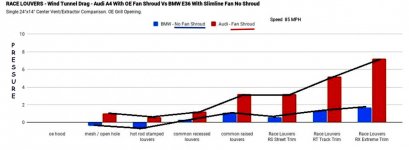

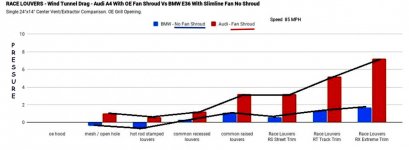

However, at a certain point in vehicle speed, 30-50mph, the airflow entering the grill from vehicle speed will become more than the cooling fan and shroud assemblies airflow and at this point the fan and shroud assembly becomes restrictive to airflow and more so at higher speeds.

Removing the entire fan and shroud assembly allows the air exiting the radiator to be unrestricted at high vehicle speeds, providing good cooling, but at little to no vehicle speed there is no airflow for cooling.

Keeping a fan but removing the shrouding removes most of the restriction at high vehicle speeds for improved cooling on track, while the fan allows for reasonable cooling at little to no vehicle speed

Good example of no shroud V having one below

Ever since GM had engine controllers and electric fans, in the tuning calibration they control at what temps, MPH and if A/C is on or off and when the fan(s) will be commanded on or off

Also considered is what coolant temp wanted and to change the Tsat opening (I tend to shim them to change their opening rate)

Then other ways to keep temps down

Water has a heat layer on top, it easily sheds that heat but has a lower temp to when it boils

Anti-freeze has a harder time in shedding that heat but boils at a high temp

For race purposes clearly not in freezing weather, so I bias the mix to more water than anti-freeze

But if in a lot of stop in go then more anti-freeze mixture then water.