This gives me heartburn and screaming spine pain just writing about all this

Starting with the C5 the normal design of tranny and location of it changed to a transaxle located in the back

Now a simple change of the release/throwout bearing means ripping out the whole ass end, transaxle and drivetube just to get

to it that then takes 5 minutes to swap out

Tearing the piss out of my 1999 C5 in 2000 as stock setup really sucked, miss shifts and clutch pedal not returning on high RPM shifts -(

Cannot have this, doing open road races moving at 160 to over 200 MPH over 100 miles of mountain hilly and over 120 turns up and down shifts are important, difference in losing or winning a race

GM designed how the clutch functioned so that some 90 pound person with no leg strength could shift 6 forward and 1 reverse gears

done by 1 shifting rod.

The stock shifter allowed an old lady to use but talk about bad and missed shifts that clunker did

I found a shop in the heart of the Kentucky mountains that for many years built racers and moonshine vehicles

They designed a shifter for C5 that was built well and had shift stops.

A lot of the issues is timing and travel

Solved in part with getting rid of stock shifter with one that allowed adjusting with shift stops.

At high RPMs like 6,500, like going from 4th to 5th gear the damn clutch pedal sticks to the floor and does not come back up on its own :-(

This is from ill design and wrong vendors used by GM

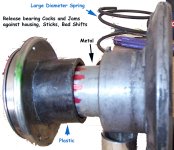

Release Bearing

The damn thing is made of metal and plastic, uses one large diameter spring

What I found is the bearing mounted to plastic would wear, and the spring caused it to cock at an angle and jam against the housing and cause of driving the bearing to pressure plate arms.

Timing of when putting the pedal to floor and the volume of clutch fluid at high RPMs caused a timing issue and overdriving the arms of pressure plate.

This in total then would do this in short timeframe

In part to solve the clutch pedal issue, I made up an adjustable pedal stop that I would adjust until it prevented overdriving pressure plate

And installed a larger clutch return spring

Lastly the design of the MN6 tranny I found a return spring inside for the shift rails, I found a way using a different bolt length to change the timing during high RPM shifts and helped greatly

Moral of story is the clutch design and adjustments is more involved than people think and ignore finding ways to better and assure correct shifting

Timing and travel, in the end the release bearing pushed the fingers of pressure plate too far inward causing then less clamping of disc

so slipping and hot spotting.

Timing, crappy shifter causes gears not fully engaging, screwing up syncros requiring tranny repairs.